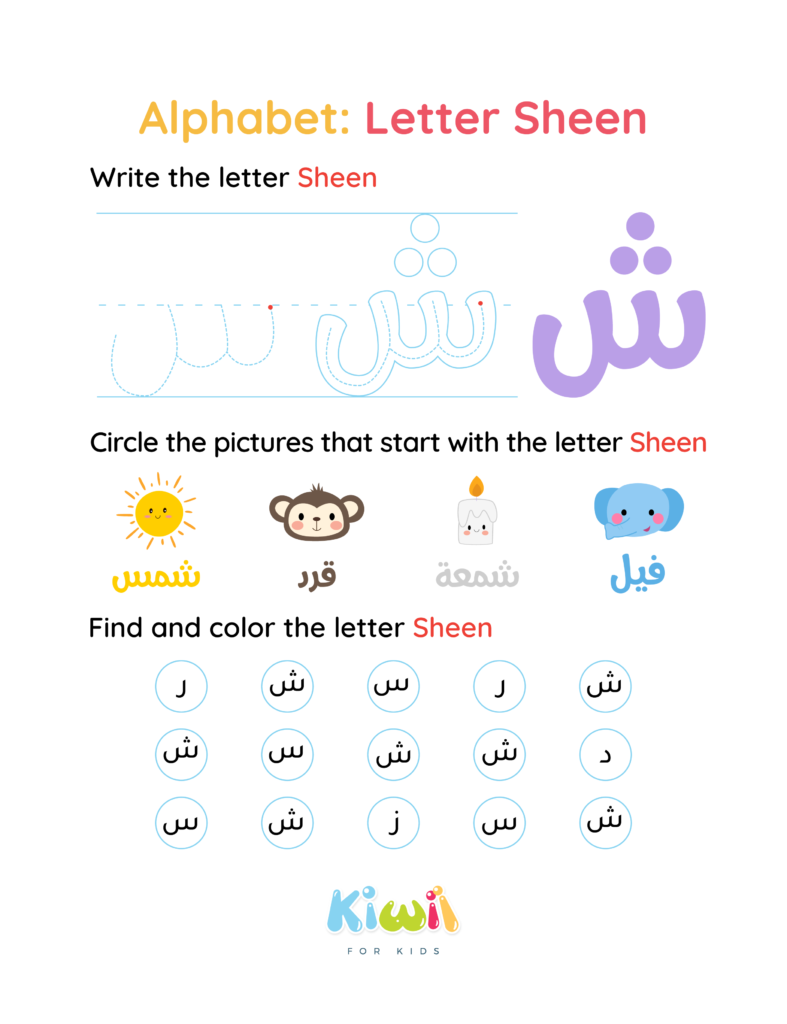

الحروف العربية للأطفال - حرف الشّين

Letter Sheen Worksheet for preschoolers and kindergarten.

ورقة عمل لحرف الشّين – لتعليم الأطفال في مرحلة التأسيس و الروضة

In this worksheet we have a Varity of exercises that will help your little kids to learn letter with fun.

- Write the letter.

- Circle The right pictures.

- Find and color.

Arabic Letters worksheets.

Cute characters, clear and simple way to make learning easy.

For personal use only.